|

Qingdao Tennry Carbon Co., Ltd.

|

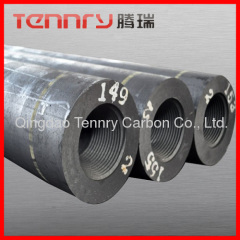

graphite electrode EAF carbon rod

| Price: | 1850.0~2500.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

EAF HP Graphite Electrode:

1.Grade: RP, HP, UHP

2.Density: 1.6g/cm3

3.Length: 800mm-2400mm

4.Dia: 100mm-800mm

5.Nipple: 3-4TPI

Product sort

Graphite electrode can be divided into ordinary power, high power and ultra high power electrode by electrode quality index.

1. Graphite electrode of ordinary power

Allowable used graphite electrode with current density lower than 17A/cm2, mainly used in ordinary power electric furnace for steel-making, silicon smelting and yellow phosphorus smelting.

2. Graphite electrode with oxidation resistant coating

Graphite electrode with oxidation resistant coating has protective layer which can conduct electricity, heat resistant and anti-oxidation, reduce the electrode consume when steel-making.

3. Graphite electrode of high power

Allowable used graphite electrode with current density lower than 18-25A/cm2, mainly used in high power arc furnace for steel-making.

4. Graphite electrode of ultra high power

Allowable used graphite electrode with current density lower than 25A/cm2. Mainly used in ultra high power arc furnace for steel-making.

Application

Arc furnace of steel-making, industrial silicon furnace and yellow phosphorus furnace.

Specifications

High temp proof: melting point of graphite is3850 C , boiling point is 4250 C, small loss even under high tempburning.

1.High purity graphite has its unique advantages: low resistivity, high temp proof, anti corrosion, good thermal shock resistance, electrical conductivity, low coefficient of thermal expansion, self -lubricating, suitable for precise process.

2.

Electrical conductivity, thermal conductivity: electrical conductivity of graphite is 100 times than normal nonmetal metal minerals, even better than that of steel, iron, aluminium, lead etc. Coefficient of thermal conductivity decreases as temp increases, graphite is even going to be a heat insulator under extremely high temp. Graphite can conduct electricity due to each carbon atoms in graphite can only form three covalent bond with other carbon atoms ,each carbon atoms remains a free electrons to transmit electric charge.

Physical and chemicalindicators of graphite block.

Model | Density g/cm3 | Resistivity µΩm | Breaking strength Mpa | Compression strength Mpa | Thermal expansioncoefficient 10-6/°C | Ash % | Graininess mm |

>= | <= | >= | >= | <= | <= | ||

TC170 | 1.70 | 10.5 | 19 | 38.0 | 2.3 | 0.3 | 4.0 |

TZ160 | 1.60 | 10.0 | 17.5 | 35.0 | 2.3 | 0.3 | 2.0 |

TZ170 | 1.70 | 8.5 | 18 | 36.0 | 2.5 | 0.3 | 2.0 |

TX170 | 1.70 | 8.5 | 18 | 36.0 | 2.5 | 0.3 | 0.8 |

TX172 | 1.72 | 8.5 | 22 | 44.0 | 2.5 | 0.3 | 0.8 |

TX174 | 1.74 | 8.0 | 24 | 48.0 | 2.5 | 0.3 | 0.8 |

All kinds of sizes can be manufacturedaccording to customer requirement.

Welcome to copperate with Qingdao Tennry CarbonCo.,Ltd.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Graphite Electrode

Graphite Rod

Carbon Graphite

Carbon Steel Electrode

Carbon Rod

Carbon Graphite Packing

More>>